Brother Dave

2016-05-16 17:25:11

What affect does adding more zinc have on hull reference?

A friend's hull ref is in the low .4s and think he would like to see it closer to .55...not sure which way it will go if we add zinc.

I know there is a whole lot to this topic and I've read a bunch on here but just wondering if it's possible to simplify like this. Adding zinc sends hul ref up or down?

Thanks!

Dave

Once and Future

2016-05-17 00:24:51

Want to know what I think? I could be wrong, but I don't think you will change that reference number by adding zinc. I think that more zincs will only make them last longer. Similar to putting on a zinc that is twice as big as the one you took off in a spot. It will last longer, but not change the voltage. Otherwise, your voltage would be changing the whole time the zinc is corroding away.

My theory comes from the fact that I have continued the zinc pattern on my boat of the previous owner. He was Canadian, and he used at least twice as many zincs as most guys would. He had them spaced out along the keel coolers, and 4 of the ones that are about 10" long on the rudder alone. I kind of like the idea because it evens out the voltage along the entire keel cooler. Plus, one year I was not careful enough about getting good contact when I put new zincs on, and 2 of them were inactive. Lucky then, that there were close ones nearby to take up the slack.

That's my two cents worth. Let me know if you try adding zincs and it turns out I am wrong!

Brother Dave

2016-05-17 04:08:37

Thanks, will do. What you said makes sense to me though...

lcharge

2016-05-18 13:55:31

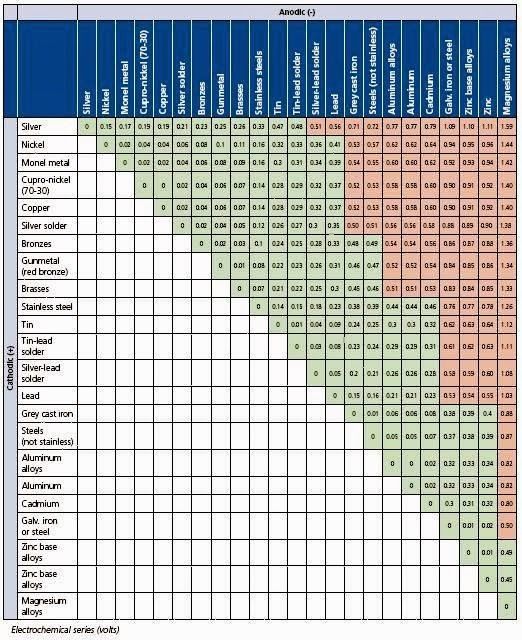

There is a little more to it than just adding zincs. If you bear with me, I have a couple of points that should help you to wrap you head around it. To start with, if you have noticed pitting on a steel plate after wire brushing the scale off, you should see that the pits are quite often evenly spaced. What happens there is that the steel for the most part is the cathode. It needs to be protected, so it designates portions of itself to become anodic (like zincs). This is the pitting. Depending on the electrolyte (water salt or fresh), the steel will decide how much anode it needs to be protected, thus the amount of pitting required to protect a surrounding area of exposed steel. A boat is the same thing. You need certain amounts of zinc in order to balance the exposed underwater metals. Now you get into the galvanic scale and each type and grade of metal has a voltage potential value rating. If you attach zinc to stainless, there will be a higher voltage created than if the zinc was attached to raw steel.

The amount of exposed metal is also a factor. Basically that is a very main point. It isn't the weight of zincs used, but the amount of exposed zinc in relation to the amount of exposed metals to be protected. If you add zinc to a steel rudder and cover it with a sealed coating, you just lost your ratio. I think normal copper paint is ok as it seems to absorb water. Saying that, I do know guys who used to leave there steel rudders unpainted in order to boost their hull reference voltage. I can't stress enough to keep your bonding connections cleaned up and connect absolutely every piece of metal to it that you can. That goes for above water as well as below. Also use a good shaft brush. Remember, that stainless or monel shaft is a big factor on keeping your hull voltage up. I just talked with a chap who has a 26' aluminum boat with a high reference voltage of .74 (I believe). After asking a few questions, I found that he had all of the hull zincs attached to his transom. It sounded like 2 of those were the big Z2 or Z3. He compare the size to a loaf of bread. I suggested that he remove some of that zinc and try to spread it more evenly about the hull. Aluminum is only protected out to about a 4 - 6ft diameter from the zincs. Just like the pitting steel???? I am hoping to hear back from him to see if there was any difference. He also trailered his boat, so the amount of zinc could be overkill.

I always like to gauge my troller's zinc size and placement so as to have them eaten down to about 1/4 size each spring. Zinc collars on the shaft are ok, but I still liked to cast one on the prop nut with a soup can each spring haulout.

Brother Dave

2016-05-18 14:41:10

Thanks for responding. Let me try it a different way if you don't mind. Generally speaking, adding more zinc will do which of the following to my hull reference?

a)raise it

b)lower it

c)nothing